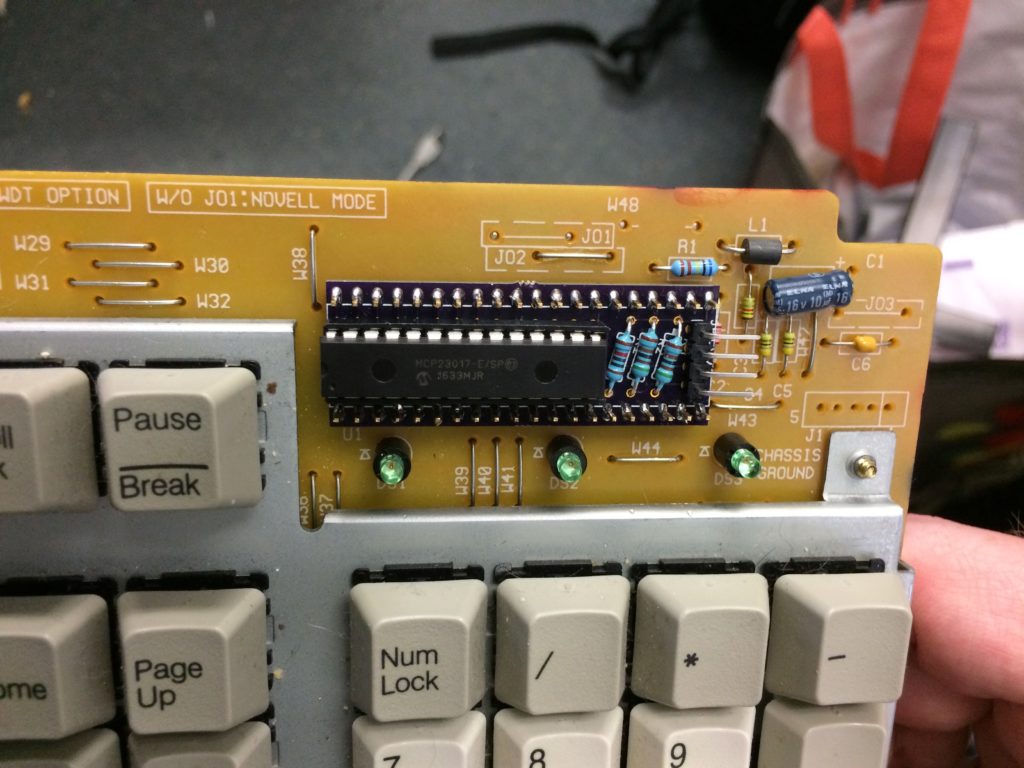

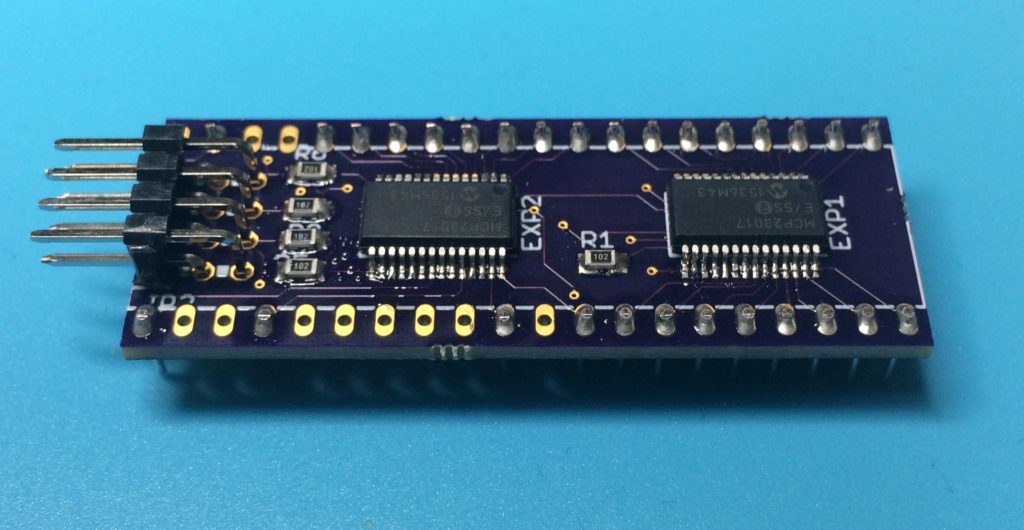

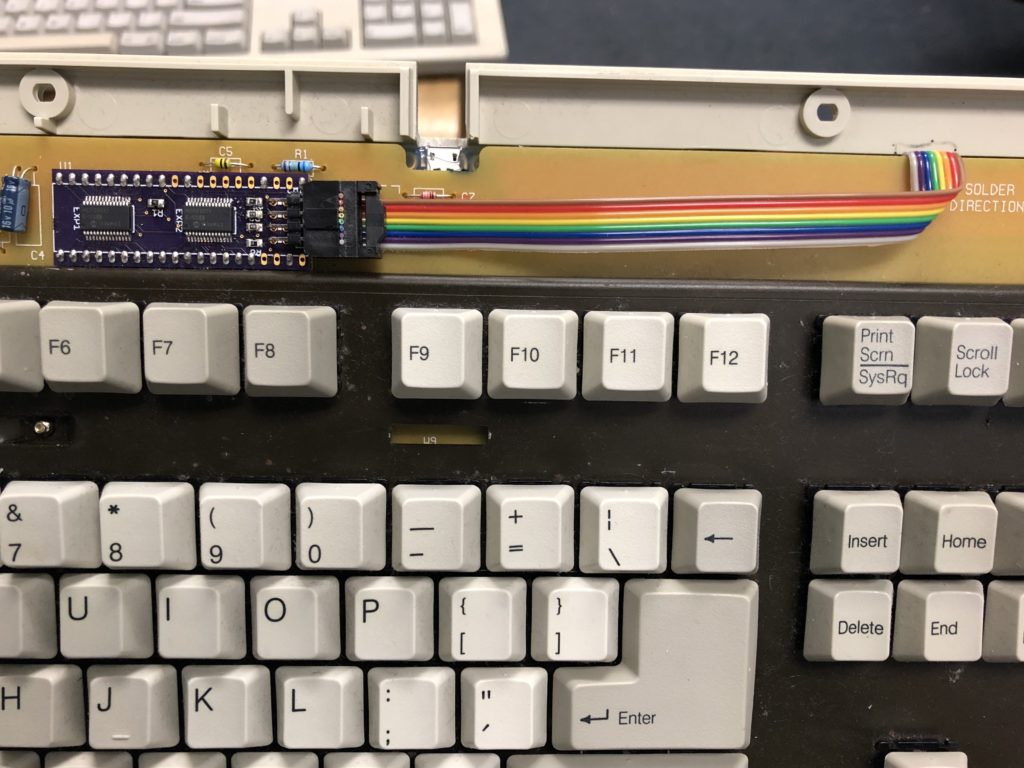

For this one I wanted to clean up the wiring to the keyboard PCB, and work towards making something that was a drop-in replacement for the original microcontroller. To this end, I bought tiny surface-mount versions of the IO expander chips, which were small enough to fit 2 on a board the size of the original microcontroller:

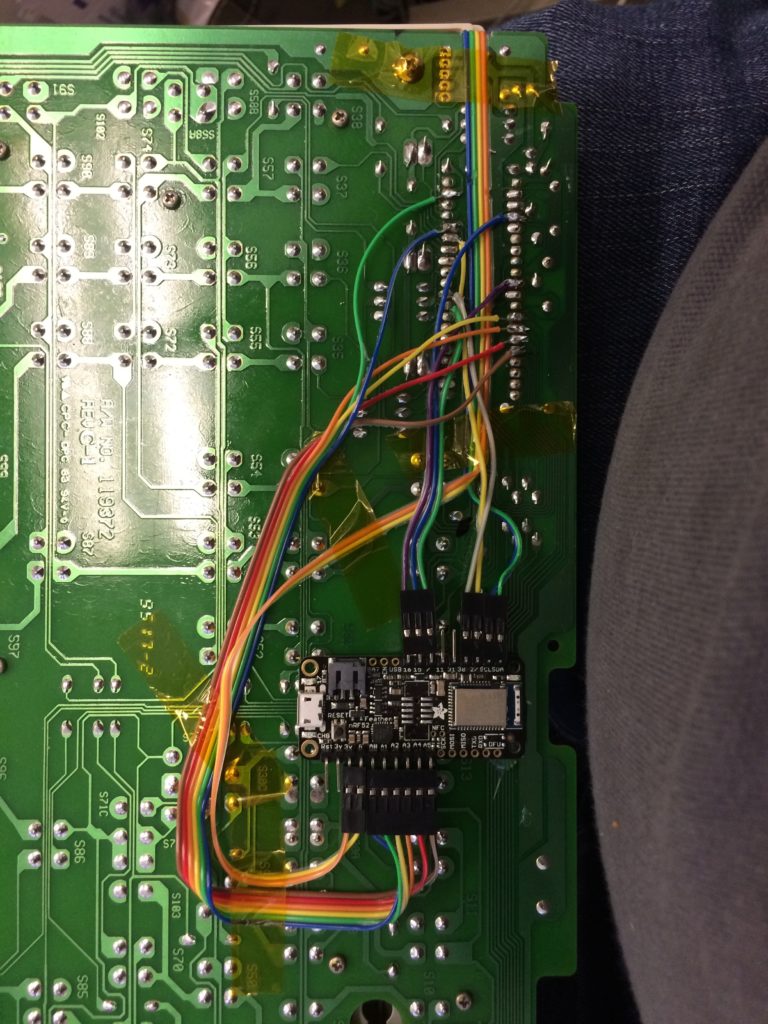

The 32 IO pins from the expanders were sufficient to connect to all of the rows and columns and LEDs. It has an 8-pin ribbon cable connector for power, ground, clock, data, and four more pins for interrupts from the expander chips. The keyboard firmware I was working with wasn’t interrupt-driven as of yet, but I wanted to have the option.

Up until this time, the pinouts I was using varied only slightly, so I had a few #defines in the code to switch between models. Since this one offloaded everything onto the expander chips, I reworked the code to be more abstracted and cleaned up.

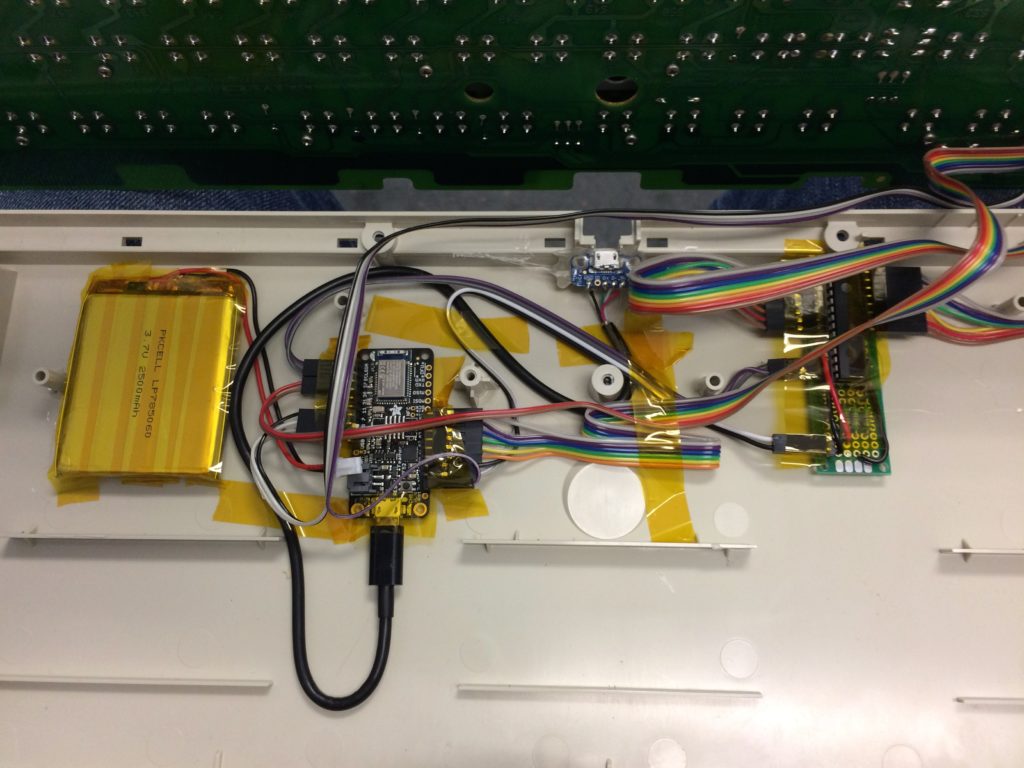

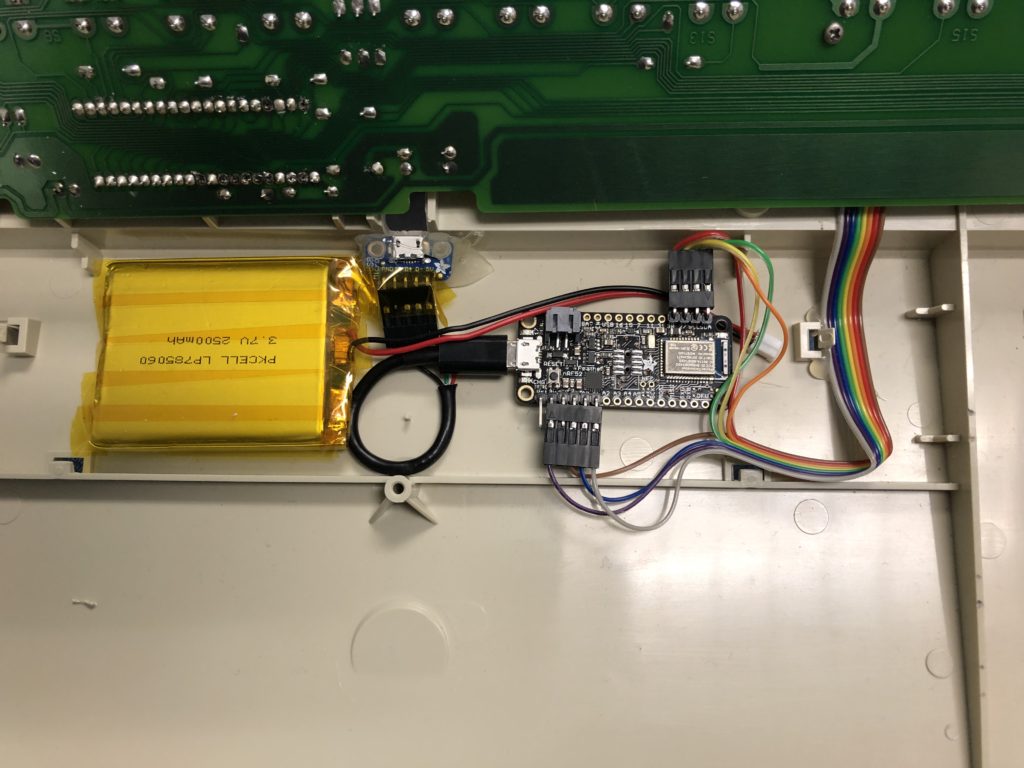

Unfortunately, this one didn’t initially work. This turned out to be for two reasons. First, sometimes the expander chips would get into a state where the startup code wouldn’t get them working. Cycling power to everything would return them all to a known state, but that was going to be complicated once it had battery power. I considered adding a button to the bluetooth board’s Enable pin, so I could power-cycle everything even when it was closed up with a battery, but some experimentation showed the better answer was to tie the Reset pins for the bluetooth board and expanders together, so the expanders got reset every time the bluetooth board rebooted.

The other problem was that it was just too slow. The abstracted code was definitely a lot slower, but even after optimizing it, it wasn’t performing to what I needed. Hitting a key very rapidly would sometimes get missed by the matrix scanning. I had assumed the IO operations going through the expander chips would be slower than the built-in IO pins, but when I did some quick benchmarking, they appeared to be between 200 and 500 times slower. Using one expander chip for the columns was fine before, because I could leave them all as inputs, and read all 16 pins in one operation. But the rows were more problematic, because they had to be cycled through, and each time the pin had to be switched between input and output; the currently-selected row had to be set as output-low, and the non-selected rows had to be set as floating inputs, while the columns could all be set as inputs with pullups. I figured even if I set things up to be interrupt-driven, the rows would still need to be scanned through, and the tests indicated it would probably be too slow.

This was disappointing, because I liked the idea of just having the option of being able switch bluetooth microcontrollers with anything else that had i2c connectivity. If I was going to go back to just using a single expander chip for the columns, I’d have to come up with a different solution for cleaning up the wiring.